illumination meaning

Systems of Lighting

The systems of lighting are as follows:

1. Direct lighting

2. Semi-direct lighting

3. Indirect lighting

4. Semi-indirect lighting

5. General lighting

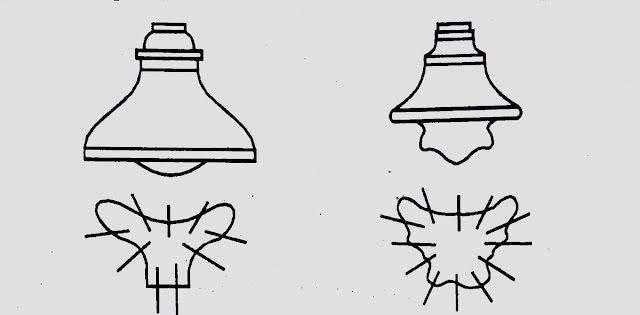

1. Direct Lighting- In this method, an opaque reflector directs 90% of the light vertically downwards. The amounts of relative horizontal and vertical efficiencies will be good and best respectively. Only 10% of the light will be absorbed in this system by the reflector. An enclosed type reflector of translucent material will direct the light vertically downwards uniformly, this system is mainly used for industrial and general outdoor lighting.

2. Semi- direct Lighting-In this method, a semi-direct reflector reflects 60% of the light downwards and remaining upwards to illuminate the ceiling It is used for general lighting where the ceiling should also be illuminated.

3. Indirect Lighting- In this method, the opaque reflectors are fitted under the lamps,The reflector will throw 90% of the light upwards for lighting the ceiling and then to be reflected or scattered from there. This gives a glare free diffused illumination with only soft shadows. It is used for decorative purposes in cinemas, hotels etc.

4. Semi-indirect Lighting- In this method, the reflector is constructed in such a way that it throws 60% to 90% of the light upwards for lighting the ceiling and then to be reflected from there, The system provides a soft lighting with a good amount of relative efficiency. It is mainly used for indoor decoration purposes.

5. General Lighting- In this method, the bulb and its reflector are made of diffuse glass, so as to give uniform illumination in all directions. Hence, the light appears to be coming from the fitting and not from the filament. A milky bulb is suitable for general lighting.

Characteristics of Good Illumination

A good illumination should have the following characteristics:

1. The reflector used with the lamp should not be of a dark colour, otherwise suitable light will not be available.

2. The source of light should not strike the eyes of the worker. It should come indirectly or by reflection.

3. First locate the lamp at a proper place and then adjust it towards the job.

4. The type and size of the lamp should be correct.

5. Keep the lamp clean so as to maintain its efficiency.

Sources of Light

The light emitting bodies are the sources of light. They are of following two main types :

1. Natural sources

2. Artificial sources

1. Natural Sources- There are three natural sources of light which are as follows :

(a) Sun- Sun is the main and greatest source of light. It gives very bright and glare light. Its light is accompanied, with heat energy. It is 1.5 x 10° km away from the earth. Its diameter is 6.96 x and surface area is 6 x 1018 km?. It produces a light and heat energy of 3.86 x 1033 Erg/second.

(b) Moon-It does not have the light of its own, but it reflects the light received from the sun. Its light is dim and cool. It is 3.9 x 10' km away from the earth. Its diameter is 1739 km and its surface area is 3.8 x 10' km?.

(c) Stars- They give a very dim light but that does not reach the earth normally.

2. Artificial Sources-The man-made sources of light ar known as artificial sources, e.g., lamps, fire, gas etc.

Types of Artificial Sources of Light

The artificial sources of light may be classified as follow

- Incandescent lamp

- Carbon filament lamp

- Metal filament lamp:

(1) Vacuum type lamp

(2) Gas filled type lamp

- Gas discharge lamps

- Sodium vapour lamp

- Mercury vapour lamp

- High pressure mercury vapour lamp

- Low pressure mercury vapour lamp

- Neon sign lamp

- Arc lamp

Carbon Filament Lamp. These lamps are not used for lighting purposes, because they radiate more heat in comparison to the light and consume more electrical power. These are used for battery charging purpose. It consists of an evacuated glass bulb having a fine carbon filament wound in a spiral shape, which is supported on two support wires, The melting point of carbon is 3500°C but its working temperature should hot exceed 1800°C. On temperatures above 1800°C, the carbon will start to disintegrate which will blacken the inside walls of the bulb. Carbon has a negative temperature coefficient, thus its resistance will reduce at high temperature and it will draw more current from the main supply. It produces a yellowish light at a low efficiency of 2.5 to 4 lumens per watt.

Metal Filament Lamp. It consists of a fine metallic wire either straight or coiled, which is called the filament. On passing an electric current through the filament, the filament will get hearted up and will start to radiate light, hence it is known as metal filament lamp. Its construction

(1) Cap- The cap may be of a bayonet or Galioth Edison screw type. The bayonet cap has two pins for making contact with holder pins,

(a). Two lead-in wires connect these pins to the support wires, which are connected to the filament. Generally, lamps having a wattage up to 200 watts are of bayonet cap type while above it are of Galioth Edison screw type (300 to 1500 watts). The Galioth Edison screw cap has one pin at its top and the other terminal of filament is connected to the threaded portion of the cap,

(2) Bulb- Bulb is the outer part of the lamp which is made of glass. The bulb is evacuated. A milky bulb is made of a light bluish-white coloured glass, so as to give a white light.

(3) Filament- The filament is made of thin wire of tungsten metal. The diameter and length of the filament wire depends on the wattage of the lamp. It is connected to two support wires through two lead-in wires which are passed through glass stem-tube. The stem-tube has a hole in it which is used to evacuate the lamp. The melting point of tungsten filament is 3400°C with a temperature coefficient of + 0.0051 and specific resistance of 60 micro ohm cm. It can work easily at 2000°C with a low vapour pressure. Its efficiency is 10 lumens per watt. Metal filament lamps are of following two types:

(1) Vacuum type

(2) Gas filled type.

(1) Vacuum Type- This type of lamps are perfectly evacuated. The filament is wound in the shape of a net, The length of filament is usually short, as they are made upto 25 watts only. Their temperature may rise upto 2000°C in vacuum condition. At higher temperature the metal will start to disintegrate and the lamp will become defective. This type of bulb produces less illumination.

(2) Gas Filled Lamp- In order to raise the working temperature of a filament the bulbs are filled with an inert gas, e.g. Argon, nitrogen etc. instead of evacuating them. The working temperature will then exceed 2000°C and it will reach near the melting point of the metal. A long filament is used which is coiled in the shape of a thin pue lengthy coil, The length of the coil will depend on the wattage of lamp. Their wattage may vary from 40 to 1500 watts.

Gas filled lamps radiate some quantity of heat also due to the presence of gas experienced. The conduction of heat will depend on the span of coil, hence the coil itself is coiled so as to reduce its span. More the length of wire, more will be the wattage and thus the light. The life of a lamp depends on its filament, and gas filled lamps have longer lives than vacuum lamps. They can work upto 2000 hours and they have more efficiency and more lumens output. The rating of a lamp is expressed in working volts and wattage, e.g., 250 volts, 40 watts.The type of the lamp is also mentioned (i.e., vacuum or coiled coil type) on the bulb. In order to obtain a long working life of a lamp, protect it from-

(1) Excessive voltage beyond rating.

(2) Vibration and mechanical shocks.

(3) Wrong fitting or loose fitting.

The working life of a lamp will greatly depend on its working voltage; they are very sensitive to voltage changes. By increasing 1% voltage, the life will reduce by 5% to 15%, and by increasing 5% voltage, the life will reduce by 50%. The lamps should be fitted on such places where they remain shock-proof and water- proof.

Special Type Lamps. There are some special type lamps also which have peculiar shapes, e.g., coloured lamp, pigmy lamp, candle lamp, night lamp etc, These lamps are generally made between zero to 25 watts in vacuum type. Coloured, pigmy and candle lamps look attractive and they are used for decorative purposes. Night lamps are also called zero watt lamps, and they are used for producing a dim light in the bed-rooms during sleeping in the night, they may be of clear or milky (day light) type.

Gas Discharge Lamps. In a gas discharge lamp, the light is not emitted by a filament, but, a discharge produced in the gas, filled-at low pressure in the lamps, emits light. The lamp has two electrodes-positive and negative. When a potential difference is applied across these electrodes, then some electrons are emitted by the negative electrode. These electrons acquire a very high velocity due to intense attraction of the positive electrode.

The movement of electrons results in collision with the atoms of the gas, and some more electrons are detached from their atoms. In this way an ionization is started in the tube. The high velocity of electrons is responsible for luminous discharge. There are two main types of gas discharge lamps which are as follows: 1. Sodium vapour lamps 2. Mercury vapour lamps

Sodium Vapour Lamps. A sodium vapour lamp produces a bright glaring light. It consists of the following :

(i) Glass tube

(ii) Electrodes

(iii) Sodium and Argon gas

(iv) Transformer

(v) Capacitor

(1) Glass Tube- It is made in the form of U-tube with a two-ply glass, as shown in Fig. 21.12. The U-tube is housed in a double walled vacuum flask so as to protect it from the changes in atmospheric temperature.

(ii) Electrodes. Two coated-electrodes are sealed at the two ends.

(iii) Sodium and Argon Gas.The sodium and argon (or neon) gases are filled in the U-tube at low pressure and the tube is then sealed. Generally, the sodium is deposited on the sides of the tube walls during initial stage of construction.

(iv) Transformer. To start the lamp, a striking voltage of 380 and 450, volts are required for a 40 and 100 watts, lamps respectively. These voltages, are obtained with a high reactance step-up transformer or an auto-transformer. The transformer used has a poor regulation, i.e., at no load the voltage is very high, bur it falls down on load. The regulation is improved by connecting a capacitor across the primary winding.

(v) Capacitor. A high voltage capacitor is connected across the primary winding of the transformer, so as to keep a high power factor. When the lamp is connected to the mains, then the tube operates as a low pressure neon lamp with a pink colour. Within 10-15 minutes, the whole of the sodium is vaporized due to the heat produced by neon lamp. As the vaporization increases, the light produced by the lamp increases, and after 15 minutes the lamp will glow with full light. The lamp emits a yellowish, bright and glaring light. It is usually recommended for street lighting. Its life ends when-the filament burns out or the negative electrode (cathode) fails to emit electrons or the vaporization of sodium is not proper. Connections of the lamp are shown in Fig. 21.13. These lamps are made in 45, 60, 85 and 140 watts ranges and they produce 2200, 3200, 5500 and 8500 lumens of light respectively. The lamp has a working life of about 3500 hours.

Mercury Vapour Lamp

A mercury vapour lamp is filled with mercury vapours (gas) instead of sodium and argon (or neon). Its working principle is identical to that of a sodium vapour lamp. These lamps are of following two types:

- High pressure mercury vapour lamp (H.P.M.V. lamp)

- Low pressure mercury vapour lamp (L.P.M.V. lamps) The H.P.M.V. lamps are farther sub-divided into following :

- M.A. type

- M.A.T. type

- M.B. type

- M.A. Type Lamp- A mereury argon (M.A. type) lamp consists of a double-walled tube. The inner tube is filled with mercury and argon gases at high pressure. The space between the inner and outer tube is evacuated. At the two ends of the inner tube, two electrodes coated with calcium tungstate or cadmium borate or cadmium silicate are sealed. These electrodes are known as main electrodes. One auxiliary electrode, which is known as starting electrode, is also sealed in the inner tube near one of the main electrodes. The starting electrode is connected to the main electrode at the other end through a high resistance, It has a threaded cap, through which its two leads are taken out for connections. The connections of the lamp are . A choke is connected in series, while the capacitor in parallel. The capacitor compensates the reduction in power factor due to choke. On switchteg ON the main supply to the lamp, an arc is produced between the starting and one of the main electrodes. At this instant, the discharge takes place through argon gas whose magnitude is controlled by the high resistance. The whole argon gas becomes conductive and the discharge will start between the two main electrodes. After initial starting, only a small amount of current will flow through the auxiliary electrode because of high resistance in the circuit, therefore, the discharge will shift between the main electrodes only. Heat is produced during discharge, the tube gets warmed, the mercury gets evaporated and thus the vapour pressure inside the tube is increased. The discharge will then take the form of an arc and the lamp will start to radiate full light. The lamp should always be used in a vertical position, otherwise the arc will burn the inner tube. If the lamp is switched off, then it will not restart again.until the inside vapour pressure does not reduce to such a value which is required for starting. The lamp will restart to emit light after 4-5 minutes of switching it on again. These lamps are designed to work at 200 to 250 volts in 250 and 400 watts sizes. Their efficiency is 30 to 40 watts per lumen. A 20 MFD capacitor for 250 watts lamp and a 33 MFD capacitor for 400 watts lamp will suit. The lamp produces suitable for street lighting and other industrial purpose".

- M.A.T. Type Lamp- A mercury argon tungsten type lamp is similar to a M.A. type lamp in construction, with the exception that a tungsten filament is used in place of high resistance, This lamp can work on A.C. as well as on D.C., because a choke is not used for blast in it. The length of the lamp is more than that of the M.A. type lamp, On switching ON the main supply to the lamp, it will start to work as an ordinary filament type lamp. The discharge tube starts warming up, and at a definite temperature, the thermal switch will operate. It will cut off a portion of the filament, the discharge voltage will increase and the lamp will thus start to emit full light. The colour of light of this lamp is more pleasing in comparison to that of a MA type lamp-due to addition of red colour produced by filament. These lamps are designed to work at 200 to 250 volts A.C/D.C. in 300 and 500 watts sizes.

- M.B. Type Lamp- A mercury vapour lamp with bayonet cap consists of two main and one auxiliary electrodes. A high resistance is connected between auxiliary electrode and one of the two main electrodes, as shown in Fig. 21.17. The mercury tube is made of quartz glass so as to withstand high temperature. The lamp has a bayonet cap mounted with three connecting pins. The choke and the capacitor are placed outside the lamp, and are connected The function of the lamp is similar to that of MA, type lamp. It can be used in any position, vertical, horizontal or at any desired angle. It requires high vapour pressure for emitting full light. These lamps are designed to work at 200 to 250 volts in 80 and 125 watts sizes, They have an efficiency of about 3 lumens per watt. A 10 MFD capacitor is used with it. It produces a bluish white light and thus it is suitable for road crossings, factories, railway stations and other ceremonial places.

Fluorescent Tube

(A) Introduction- A fluorescent tube is a 'low pressure mercury discharge tube: Originally, these tubes produce a greenish light at a low efficiency. This drawback is overcome by coating the inside walls of the tube with a fluorescent material. These materials are also known as phosphors. A phosphor material has a property of absorbing the radiations of one wavelength re-emitting that in lower wavelengths. The white colour is a mixture of seven different colours pue having different wavelengths. (The colours are-red, orange, yellow, green, sky-blue, blue and violet). There are invisible rays also other than red to violet coloured rays, which can be converted into visible rays by using proper phosphors. These invisible rays are known as ultra violet and infra-red rays. The commercial phosphors excited by the mercury resonance radiation are given in the following table: Here, A = Angstrom = 10-8 cm. It is a small unit which is suitable for the measurement of very small wavelengths. By using a suitable mixture of phosphors, a variety of colours can be produced.

(B) Construction- The low pressure mercury discharge tube is made in the form of a long tube coated with a phosphor from inside. The tube contains mercury and a small quantity of argon gas at a pressure of 2.5 mm ofi mercury. Two tungsten electrodes are sealed at the ends of the tube, as shown in Fig. 21.18. The electrodes are coated with a layer of electron emitting material. The two filaments are cciitected to a pair of external pins on each end of the tube with lead-in wires. No starting anode is used with the tube, but it requires a high voltage in the start. For this purpose, a choke is connected in series with the two filament electrodes, The choke provides a high voltage impulse for starting the tube alongwith a starter. A starter is a small glow-tube which acts as make and break device.

(C) Function- When the tube is supplied with A.G., then the current completes its circuit through the choke and stater. The starter produces a make and break in the circuit, and thus a high voltage of the order of 700-1000 volts is developed across the choke. Tube electrodes get warmed up at the high voltage and start-emission of electrons. The whole mercury is vaporized and a discharge is set up between the two filament electrodes. Now, the tube will start to radiate full light while the starter is left open. Under running condition, the current flows through the discharge tube and its amount is considerable. Now the choke will act as a reactance and it will produce a back e.m.f. of about 110 volts. Thus, the voltage across the tube will be 230 - 110 = 120 volts only. A capacitor is connected across the supply terminals, so as to increase the power factor. The following table shows the length, wattage, intensity of light etc. of the tubes working, at 200-250 volts:

(D) Function of main parts.

(1) Choke

(a) It produces a high starting voltage for warming up of the electrodes so that they may start emission of electrons.

(b) It reduces the voltage across the tube under running condition.

(c) It controls the amount of current.

(ii) Starter- It works as a make and break device in the tube circuit and thus builds up a high voltage surge. The OFF and ON functions are performed by the bimetallic strips, thus a capacitor (usually 0.05 µF) is connected across the starter so as to reduce the sparking and the electrical interference to a nearby radio receiver.

Choke and Starter of Fluorescent Tube

(A) Choke- It consists of a coil wound with enamelled copper wire on laminated iron cores. It is connected in series with the tube. When the circuit is on, then it works as an auto transformer and raises the voltage upto 1000 volts. The high voltage warms up the tube electrodes, which starts the electron emission to start the radiation of light. As the tube is lighted, the choke will no more act as auto transformer. But, now the choke will act as a reactance, which will oppose the applied e.m.f, and thus will reduce its magnitude a required value.

(B) Starter- A glow type starter is used with fluorescent tubes out of two types of starters-

(1) Thermal type starter

(2) Glow type starter

A glow type starter works on the principle of dissimilar expansion in the two parts of a bimetallic strip. It consists of a small glass tube filled with helium gas. Two bimetallic strips are placed in the tube at a distance of few millimetres, When A.C. is supplied across the two strips, then a discharge is set up through the helium gas. The red coloured discharge warms up the bimetallic strips which then get closed, Now, the current will flow through the bimetallic strips instead of the gas. Hence, the gas is cooled down. The reduction in temperature wil break the circuit because now the strips will remain no more short-circuited. Again the conduction of current will start through the gas. By repetition of the above action for 4 to 5 seconds, a high voltage will be developed across the filaments. The high voltage will warm up the tube electrodes which will start the electron emission to start the radiation of light. As the tube comes, under, running condition there will remain no function of the starter, so it should be switched off. Since, the major portion of the circuit current is now tlowing through the tube, thus the current through the starter will be negligible, hence the starter will remain open circuited. Moreover, the voltage across, the tube is also reduced to nearly half the supply voltage, thus it will also hot allow the starter to conduct may current through itself.

Different Tube Connections

(A) Connections of a Tube with D.C- A fluorescent tube can be operated with D.C., but it does not operate satisfactorily. It consumes more electrical power and its one end becomes black within few days of operation. The choke does not control the magnitude of current, but it only developes a high voltage for few seconds in the start. Hence, a variable resistor has to be connected in series with the choke, The resistor produces a voltage drop and thus causes more consumption of electrical power. A push button is used in place of a starter, which has to be operated again and again till the tube does not start.

(B) Connections of Two Tubes in Series- Two fluorescent tubes can be connected in series, but the rating of the choke should be equal to the sum of wattages of the two tubes, as shown in Fig. 21.22. For two 20 watts tubes a choke of 40 watts will be required.

(C) Connections of Two Tubes in Parallel- In order to obtain more light, two fluorescent tubes are fitted on a single base. The connections are Each tube uses a separate choke and a separate starter A capacitor is added in series with the second choke, so as to improve the power factor.

Arc Lamp

Two carbon rods are placed end to end connected to a d.c. source of not less than 45 volts and drawing considerable current. Now, if the rods are drawn about 1.5-6 mm apart, an arc will be formed between them. This principle is utilised in arc lamps. In D.C. operation the positive rod should be kept thicker than the negative rod, while in A.C. operation the thickness of both the rods remains the same. For operating the circuit, at 220 volts D.C., a series resistor is used, as shown in Fig. 21.24, In this lamp, 85% of the light is emitted due to the positive carbon electrode having temperature of 2500°C-4000°C. The negative carbon electrode emits only 10% of the light at 2000°C-2500°C. The remaining 5% light is emitted by the arc between the two electrodes. Now-a-days, metallic electrodes are used Jn place of carbon-electrodes, but the utility of these lamps IS limited upto cinema projector, search light and photography etc.

Neon Tubes (Neon Sign Lamps). These tubes are not used for lighting purpose, but these are used for advertising purposes as neon-signs and letters. The tube can be moulded in any required shape. The length of the tube varies from 2 to 5 metres, and the diameter varies from 10 to 20 mm. Two electrodes are placed, one on each end. Different gases are filled so as to obtain different colours-

- For orange-red colour- Neon gas.

- For blue colour- Neon and argon gases with small quantity of mercury.

- For green colour- Yellow glass, neon gas with mercury.

- For yellow colour-Yellow glass, helium gas.

(a) Fault- Neon tube fails to operate- Causes

(1) Primary side connections are wrong.

(2) There is a short-circuit or earthing in the primary side.

(3) The transformer is defective.

(b) Fault- The tube is flickering- Causes

(1) Primary side connections are loose.

(2) Primary voltage is low.

nice sir

ReplyDelete